- Perfect layers paste mask how to#

- Perfect layers paste mask pdf#

- Perfect layers paste mask pro#

- Perfect layers paste mask series#

Once it is installed, open your board file back up. Head over to their website, and get a copy installed on your computer. I choose Bullzip for no particular reason. If everything worked correctly, you should see the tCream layer with no fill inside the boxes!Īt this point you will need a. Click the Fillstyle option and change it to solid.

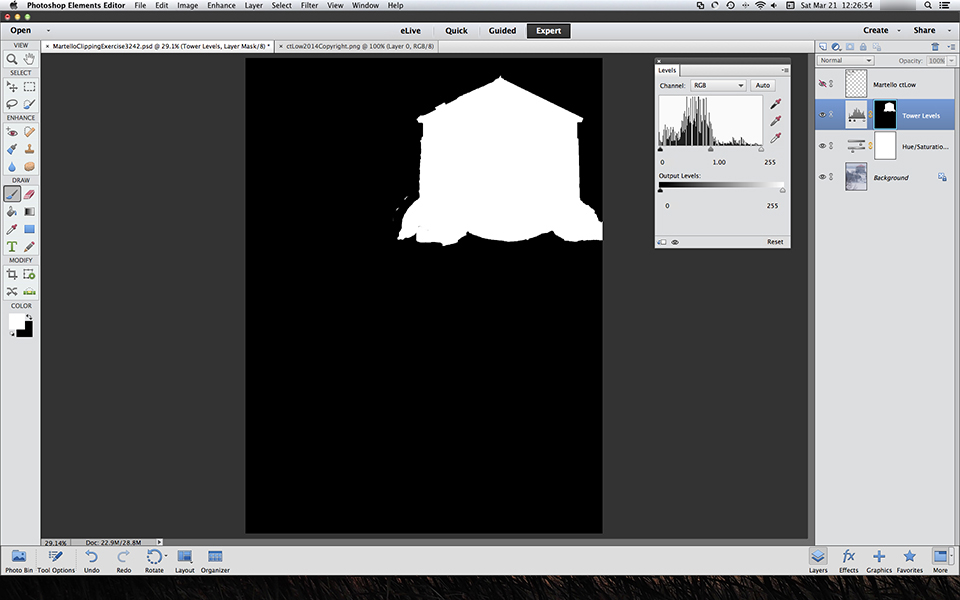

To remove them, select the tCream layer and hit the Change button. If we leave it there, the cutter will cut along all of those lines. This is good, but we don't want the cross hatching fill. These are the pads that the paste will go on. You should see something like the picture below. Next, go to the Display button (also under View -> Display/hide layers.) Turn off every layer except for tCream. We don’t need to see these layers for long anyways. Don’t worry about it if you don’t have the hot keys. If you use SparkFun hotkeys, F8 and F11 will get you our ‘standard’ layers view. Now we want to prepare a file to be cut out. You can get your board made however you would like.

Perfect layers paste mask pro#

I have submitted my files to BatchPCB and, in the blink of an eye, have a plain Arduino Pro board.

Perfect layers paste mask series#

If you have never used Eagle, there is a great series of tutorials right here that will get you going! I am going to skip over all of that and get right to the goods though. Step 1 – Design your PCB and get it madeįor convenience, I am going to use the Arduino Pro eagle files found on the SparkFun website. Be warned though, it will take some practice to get your files to cut out in the orientation and location you want without using the plugin.

If you wanted something free, Inkscape would do the trick. Craft Robo Pro has made a plug-in for Illustrator that makes it easy to orient your files to be cut. Skillet (or anything to reflow the board)

Perfect layers paste mask pdf#

Bullzip PDF Printer – A free PDF printer.Requirementsįor this tutorial, I will be using the following software: In this tutorial we are going to talk about making solder paste stencils out of board files in Eagle. But what was the secret? How did they do it? Well in no time at all, I had my answer. We had heard rumor of people creating their own stencils using vinyl sheeting and a plotting cutter. Especially if they are prototypes and their design could change. Not very practical for building one or two boards. They are strong and last for thousands of builds. I needed to be able to apply solder paste quickly and easily. That would be very tedious and time consuming. I didn't want to have to solder each component on by hand.

Perfect layers paste mask how to#

There was still one problem though, how to solder the SMD components. Surface Mount Devices (SMD) are very small and take up less space! I had never considered using surface mount components before, but since I had the resources available to do so, the time had come to learn. But of course! Use surface mount components. If only there was a way to make the board smaller, but still get the functionality that I needed. The increased area of the board also drove the cost of the board up, very high. Trying to pack this board with through-hole components like resistors and transistors was challenging and resulted in having to increase the board size larger than I would have liked. Recently, however, I started designing a PCB that has lots of LEDs, lots of rotary encoders, and lots of outputs to relays. When I was hired at SparkFun, I made the switch from Altium to Eagle, and instead of milling my PCBs, I had easy access to BatchPCB. I no longer had to spend an entire day soldering jumper wires around a perf board, crossing wire after wire, only to find out that something wasn’t working. For me, making the jump from breadboards and perforated PCB to creating schematics in Altium and using a PCB mill was huge. Surface mount components often intimidate people.

0 kommentar(er)

0 kommentar(er)